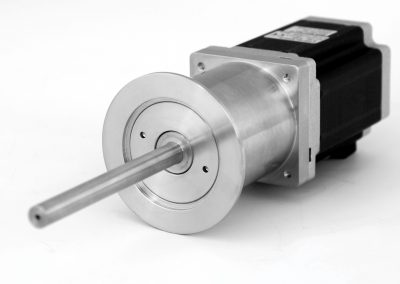

Rotary Vacuum Feedthroughs

Ferrofluid sealed

Home » RotaryVacuum Feedtroughs » Ferrofluid sealed

BeamTec has extended its product range of rotary vacuum feedthrough with magnetical sealing technology. The hermetical seal is achieved using o-rings made of a magnetic fluid around the rotating shaft. Specially shaped shafts and housings in combination with strong magnets ensure that the ferrofluid forms a smooth and flexible yet vacuum-tight barrier.

Ferrofluid feedthroughs have several benefits over conventionally sealed feedthroughs, including:

Improved reliability: Ferrofluid feedthroughs use a magnetic seal that is resistant to wear and has a longer lifespan compared to mechanical seals.

Increased vacuum performance: Ferrofluid feedthroughs provide an ultra-high vacuum seal that is not possible with mechanical seals.

Lower maintenance: Ferrofluid feedthroughs do not require regular maintenance like mechanical seals, which can be prone to leaks and wear.

No contamination: Ferrofluid feedthroughs do not introduce contamination into the vacuum chamber, making them ideal for applications where a clean environment is critical.

High temperature tolerance: Ferrofluid feedthroughs can operate at high temperatures, making them suitable for demanding applications where high temperatures are present.

Overall, ferrofluid feedthroughs provide a reliable, low-maintenance, high-performance solution for transferring rotating motion in a vacuum environment.

Typical applications are any kind motion transfer that require rotational movement in vacuum systems such as substrate holders, transport rolls or swivel blinds.

We provide a wide selection of different models or the possibilty to design and manufacture custom feedthroughs according to your specifications.

A selection of feedthroughs can be found in our Onlineshop.

Features & Benefits

- Hermetic sealing

- High vacuum compatibility

- Long maintenance intervals

- High rotation speeds

- Transfer of high torque

- Optional cooling

- Custom solutions

We are happy to send you up-to-date product information on request via info@beamtec.de.